Hi there,

I've been asked by lots of people what sort of 'kit' you need to do this sort of thing. The answer is you don't NEED much but once you start, you can kind of get carried away with it (well it did in my case) and before you know where you are, you've filled up a room!

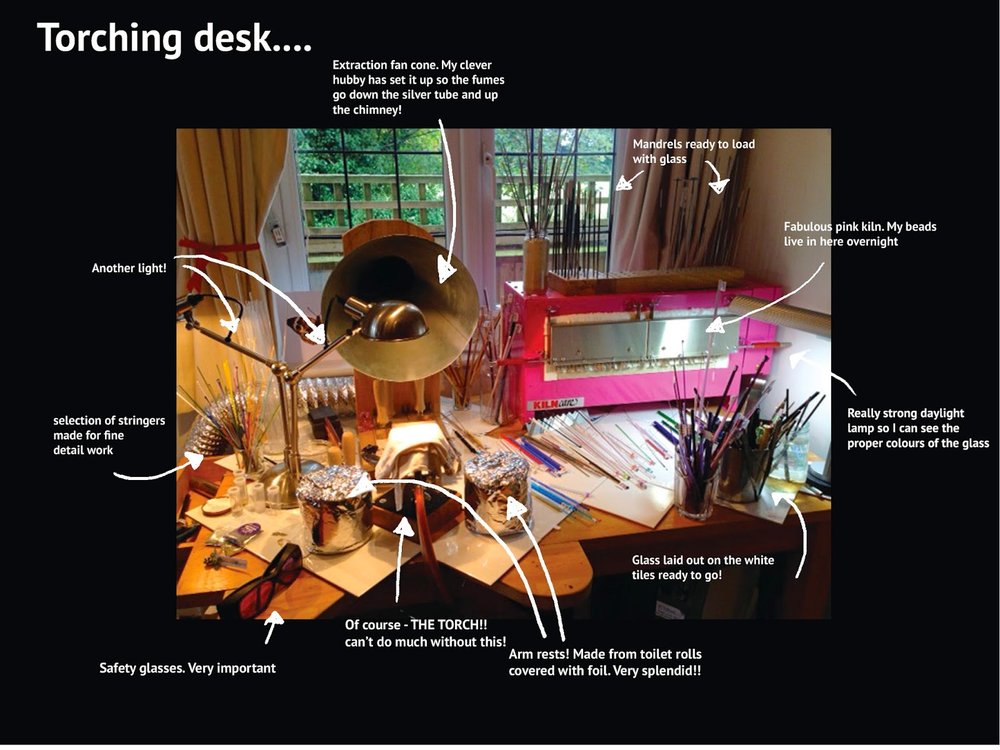

I thought it would be nice to give you a little tour of the workshop so you could see where it all happens....

The main place where glass gets melted and beads get made happens here where the torch is. I've put it in front of a window here, but I'm note sure it helps much. I think I can see the flame better when there isn't so much natural light actually.

So each bead is begun by winding molten glass onto the mandrel in a similar way. From then on the colours, techniques, treatment possibilities are endless for the glass which means that no two beads ever come out the same!

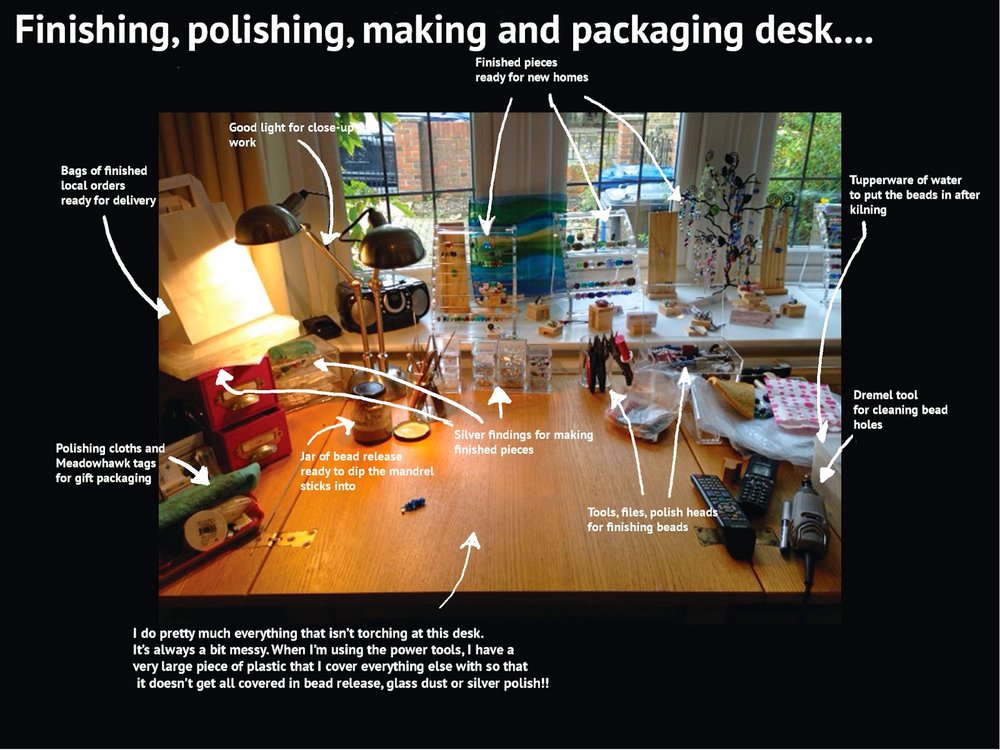

Then once the little beadlets come out of the kiln they go over to the other desk where I do pretty much everything else.

There are quite a few stages to the process.

I tend to make finished jewellery from my beads whereas some people choose not to do the silver-work bit and just stick to the making part.

Firstly the mandrels still loaded up with a bead on each get soaked in a tepid water bath, with maybe a bit of fairy liquid for good measure. This loosens the bead release and makes the beads easier to get off the stainless steel sticks. I now have an amazing set of 'vice-grip' pliers (I think that's what they are called). I got them for Mother's Day and they make taking the beads off the mandrel a real joy compared to what it used to be like!

I sometimes get one that is a bit naughty and I need to get the hammer out. Uh Oh....(If the hammer has to come out to get the bead off the mandrel it nearly always spells a quick demise for that particular bead, but

sometimes

it just needs a quick tap and the bead comes off the mandrel unscathed).

Then it is power tool time! Yay! I do love a bit of power toolage!! I clean the beads out manually with a diamond dust tipped file called a 'reamer', then (especially in the case of transparent cored beads) it is great to use a Dremel with a diamond dust tipped bit and scoop out all the residual bead release skulking in the nooks and crannies of my beads' holes. `once this is done the hole is as clean as a whistle and the light reflects into the bead so much more beautifully.

Next, lots of things can happen. I then use sterling silver findings and elements to put the jewellery together. Chain, other beads, cores, cords and ribbons are all utilised go into trying to do the best for the little beadlings, and show off their assets so that some lovely person might decide they want to take the little 'sparkly-pants' home with them!

I do the gift-packaging and notecards at this desk too.

So there you have it. A little guided tour of the workshop.

While I'm here I will share a few picks of bits I've been working on:

Scarlet/Black Poppy Ring Topper

Focal pendant to be worn on Troll or Pandora necklace

Smoke/Slate neckace and earring set

Mega colourful bracelet

this one is a beauty...

I particularly like the metallic bumpy bits!!! ;-)

Do drop me a comment or email me at:

chelleholly@btinternet.com if you have any particular questions or enquiries. Take care x